Wind Tracking and Blade Adjustment

Long-term Maneuverability

Wind turbines must be aligned optimally to the wind in order to prevent extreme loads and allow cost-effective operation. Wind turbines adjust automatically due to active systems with azimuth drives and gearboxes.

Slewing gears turn the nacelle into or out of the wind. They serve to position the machine room in such a way that the surfaces of the rotors are perpendicular to the wind.

In order to optimize the power curve of the wind turbine, the blade angle must always be adjusted according to the wind speed. The rotor blade angle can be adjusted using electric or hydraulic drives. Schaeffler offers bearing supports for both systems.

Input Shaft, Planet Gear & Output Shaft

Schaeffler offers bearing supports for slewing drives for nacelle and blade angle adjustment from one source.

Challenges for the bearing support:

- High loads

- Oscillating motion

- Vibration

Input shaft

Advantages

- Higher speeds

- Reduced heat generation

- Lower energy consumption/increased efficiency

- Lower overall costs

Planet gear

Advantages

- Simple to mount on the planet gear

- Cost-effective overall solution

- Compact solution with optimized mass facilitates downsizing

- High radial load carrying capacity

- Suitable for higher accelerations (FAG cylindrical roller bearing RN)

- High power density (INA cylindrical roller bearing RSL)

Features

- Cylindrical roller bearing with cage without outer ring

- Raceway is integrated in the planet gear

- Reinforcement of planet stud by enlarged radius on one side of the bearing

Output shaft

FAG cylindrical roller bearing – Advantages

- Non-locating bearings with displacement within the bearing

- High radial load carrying capacity

- Simplified mounting and dismounting due to separability of the cage bearings

FAG spherical roller bearing – Advantages

- Can be used as locating and non-locating bearings

- Optimized internal bearing design for high demands

- Angular adjustment facility

FAG tapered roller bearing – Advantages

- Narrow guidance of shafts due to clearance-free setting

- High bearing rigidity due to large support base of pressure cones

- Suitable for high radial and axial loads

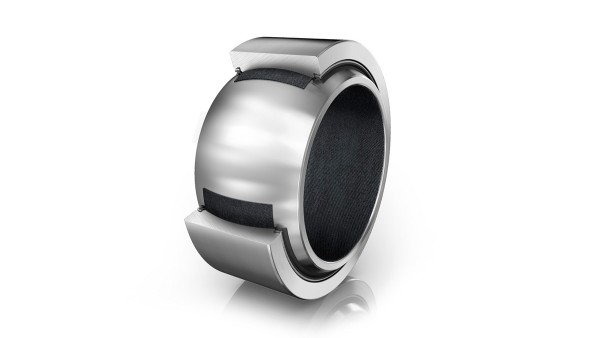

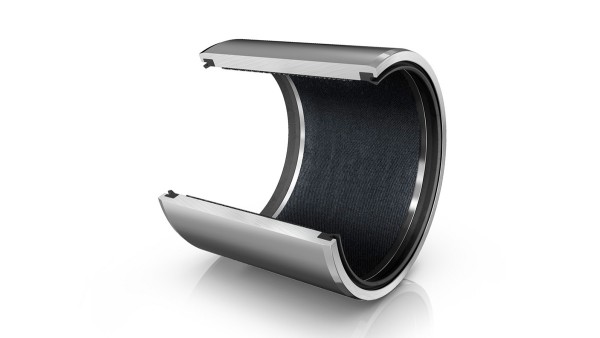

Spherical Plain Bearings and Plain Bushes

Advantages

- Long operating life

- High load carrying capacity

- Absolutely maintenance-free due to ELGOGLIDE

- Protected against contamination

- Corrosion protection with Corrotect

Features

- ELGOGLIDE sliding layer

- Sealed on both sides